The means in which a building, a bridge or any type of improvement is designed and constructed is an important consideration prior to beginning a project, as it has a significant impact on cost, risk and the overall schedule. The sections below describe the most commonly used construction project delivery methods.

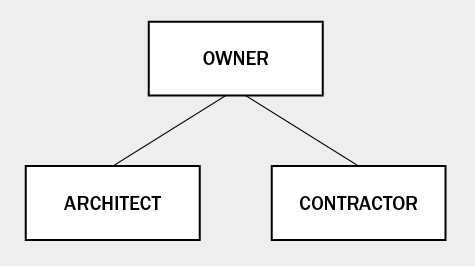

Design-Bid-Build (DBB)

This project delivery method is the “traditional” means of delivering a construction project, and creates a clear separation between the design and construction process.

Typically the only criteria for selection of a contractor in design-bid-build (DBB) projects is the lowest construction price. To begin the DBB process, an architect or engineer (A/E) is hired by an owner to create design documents (drawings and technical specifications) for a project. In addition, the A/E will usually develop a project cost estimate and schedule. Once the design documents are completed, a Request for Bids (sometimes called a Request for Proposal) is created a released to contractors. Contractors will then evaluate the project documents and provide a price for the work. The A/E is responsible for answering bidder questions and for assisting the owner in evaluating the received bids. Once a bid is selected, the owner establishes a contract with the chosen contractor and work begins on the project.

Having been the traditional means of delivering projects, the DBB method is typically the most familiar to those in the industry. It also has, in theory, the ability to deliver a low-cost project. However, since this method isolates the contractor from the design process, there is a high potential for project cost increases due to conflicts between the design documents and the constructability of the project in the field. Also, selecting a low bidder can result in a decrease in the quality of the finished product, as the contractor must often determine ways of achieving a profit on the job, working under a budget that was the lowest of all contractors submitting pricing.

In general, the DBB process is best used on projects that are simple, that are not under a tight time crunch and that have a limited budget.

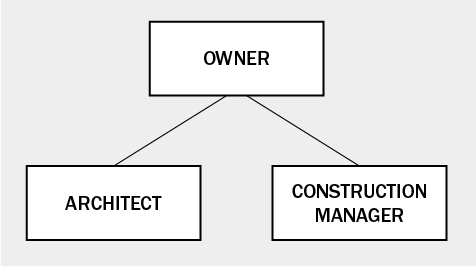

Construction Manager at Risk (CMAR)

CMAR stands for Construction Manager at Risk, and is a relatively new type of project delivery method. In a CMAR project, the owner selects a “Construction Manager” (CM) who is responsible for building the project. The selection of the CM is made using criteria in addition to the construction cost, such as quality, proven track record, detailed project approach and ability to meet the schedule of the project. In this delivery method the design work and construction work are contracted separately.

The selected CM becomes a project team member early on in the project process and, working directly with the owner and the A/E, provides input as the project moves through design into construction. The CM provides input on items such as project budget, construction cost estimating and the overall schedule as well as providing review of design drawings to identify constructability issues and potential cost savings. Typically the pricing of the construction is begun early in the design process, and is refined as the design progresses with a final guaranteed maximum price (GMP) provided to the owner prior to beginning of construction. The GMP is typically comprised of a cost-plus-fixed-fee structure, where the actual project costs for labor and materials are passed through to the owner, and the CM charges a fixed fee on top of that amount. Though owners typically work with trusted contractors in this type of delivery method, it can be difficult to determine if the established maximum price is reasonable for the type of project constructed.

The CMAR process is most successful in projects that have a large undefined scope and are under pressure to finish in a limited time. This process may also be applicable to some projects that involve complex integration between disciplines or multiple phases of construction, where the oversight and coordination delivered by a construction manager is extremely beneficial.

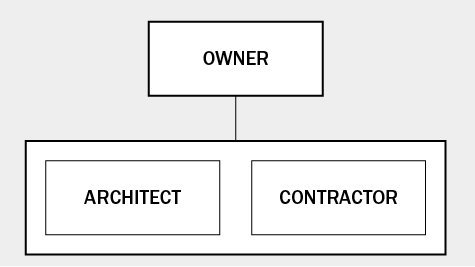

Design-Build (DB)

In a design-build project, the owner hires a company or team under one contract to deliver the construction project from start to finish. Since the team is responsible for both the design and the construction components, pricing changes are kept to a minimum, and are usually isolated only to those instances where unknown conditions or owner requests necessitate cost increases. If DB entities are comprised of more than one company, it is important for the owner to identify the working relationship between the members of a potentially selected team in order to minimize conflicts further down the road.

The DB method provides the ability to deliver a project on a tight schedule, as projects can be split up and delivered in a package approach, where individual components are designed and built as needed to achieve the final completion date. Generally the owner can establish a firm maximum price of the project early on, and has a significant amount of cost control.

Design build is typically used for construction projects where the owner has clearly established the requirements prior to design. It can also be an appropriate method when schedule is a concern, as it removes the components of the schedule that would typically be consumed by the bidding and procurement process.

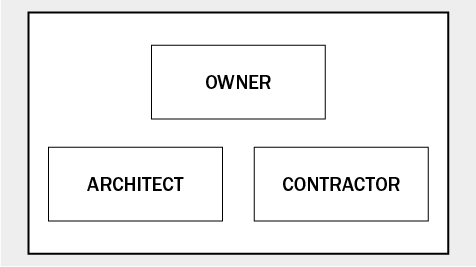

Integrated Project Delivery (IPD)

Integrated project delivery (IPD) is relatively new delivery method, having made significant inroads into the construction industry only in the last decade. In this delivery method the owner selects an A/E and CM prior to the kickoff of project design. A joint contract is signed between the three entities after goals and objectives are established collaboratively. This delivery method incorporates early participation from the contractor, which can lead to a streamlined design that is directed specifically towards a project objectives. Similar to the CMAR process, the owner must remain highly involved in the project as a crucial member of the project team. Integrated project delivery provides opportunities for minimizing project costs and increasing efficiency through cooperation of the team members.

It is important to note that the owner, A/E, and CM are legally bound into a single entity so risk that is normally assigned to one party is now spread to all parties, which is uncomfortable for many owners. However, the increased collaboration among the parties is thought to reduce the overall risk.

IPD is best suited for projects in the private sector that are complex, under a tight schedule or may be largely undefined. Public entities normally cannot use IPD as a delivery method due to the lack of a bidding component.

Public-Private-Partnership (3P)

The public-private-partnership (also known as P3 or PPP) delivery model is commonly used outside of the United States and is slowly making inroads into limited areas of domestic US public projects. In the design and construction industry, the P3 model involves a contract established between a government entity and a private corporation to fund, construct/renovate, and usually operate and maintain, public infrastructure. In return, the private entity will receive income that is generated from the project (for a pre-determined time period) in order to pay back, and eventually profit from, the investment. For example, a private corporation may agree to fund the construction of a light rail system within a city under an agreement that the corporation will receive a specific percentage of the revenue that is generated from the ridership fees.

Some of the benefits of P3 are:

- Taxpayers may be relieved of some or all of the burden related to project funding or the taxpayer funding may be spread out over time

- Private entities are typically seen to provide greater expertise and efficiency in construction and operation than the public sector (as there is profit motivation)

- The public entity can still provide regulation over the operation of the infrastructure to help maintain proper operation

Utilization of a P3 model brings with it the understanding that a certain amount of risk must be taken on by the public entity. The profit motivations that drive private corporations to be efficient can also create shortcuts in operation and maintenance that lead to problems down the road. Public entities need to balance budgetary issues with the amount of control that they are willing to hand over to private entities. In addition, at some point the public entity will need to take over operation of the infrastructure when the contract has ended, or will need to solicit bidders for another contracted period of operation.

Job Order Contracting (JOC)

Another construction project delivery method is Job Order Contracting, which allows an owner to hire a contractor for repetitive tasks at a specific unit cost. This is generally used for renovation or small deferred maintenance projects that can be well defined with unit costs.

A contractor and owner will develop a contract that includes a list of tasks and related unit costs that will be valid for a specific timeframe or up to a specific dollar value. This occurs through a bid process where multiple contractors present their unit prices for the work. As projects are identified, the owner will assign the tasks to the contractor to perform the work.

The main benefit to the owner is that the work can be assigned and completed quickly once the contract is executed.

Why Architects Should Understand Construction Project Delivery Methods

Architects must understand construction project delivery methods because the contractual obligations may vary between them. The project manager and project architect must read and understand the contract so that they follow the requirements.

In addition, an architect's responsibility may vary between phases. This can affect the size of the team throughout the project, which will affect the architect's fee, cash flow, and profit.