Air conditioning operates based on the principles of phase conversion, which is the transformation of a material from one state (or phase) of matter to another, such as when a material changes from a liquid to a gas. When a liquid to gas change occurs, the material absorbs heat. Conversely, when the material changes from gas to liquid, it releases heat. An air conditioner is basically a machine that forces phase conversion and uses the resulting heat transfer principles to cool buildings.

Air conditioners are comprised of many components, the primary ones being a fluid compressor, a condenser and an evaporator coil. We will pick a point in the air conditioning cycle and describe how the movement of the refrigerant through the system works to cool a building. Since the compressor is one of the most vital pieces of equipment in an air-conditioning system, let’s start there.

Air Conditioning Cycle

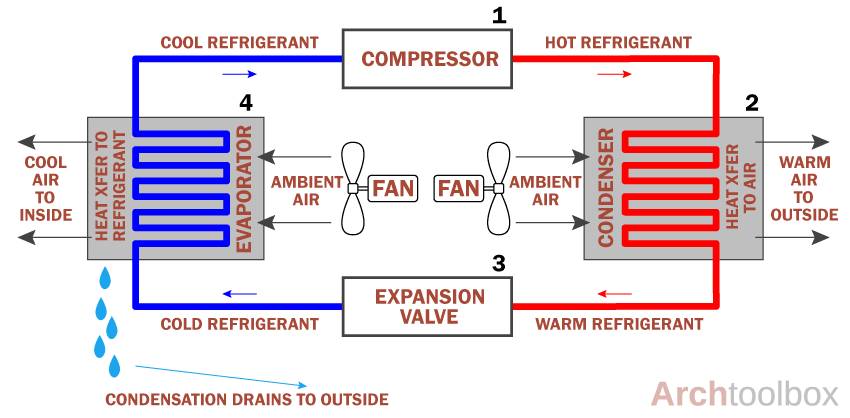

All air-conditioning systems utilize a specific material to undergo the phase conversion process. This material is called a refrigerant, and is contained within tubing which runs throughout the air-conditioning system. The refrigerant is pulled into the system’s compressor (item 1 in the diagram below) in the form of a warm vapor after leaving the evaporator coil (which will be explained further below).

The compressor increases the density of the incoming refrigerant vapor, causing it to increase in pressure and temperature. This is normally accomplished using a centrifugal system, where a series of spinning blades rapidly forces the vapor to the outside of the compressor chamber, at which point it exits. This hot, high-pressure vapor then travels to the air conditioner’s condenser (item 2) where it moves through a series of coils with thin metal fins attached. A fan blows air over the fins, and heat moves from the refrigerant to the fins and into the air stream, very similar to the method a radiator uses to remove heat from the coolant circulating within in a car engine. The air that is run over the condenser coils is vented to the building exterior and is released to the atmosphere.

This trip through the condenser causes the vapor to lose a significant amount of heat and it subsequently changes phase from a gas to a high temperature liquid. The liquid refrigerant is then forced through an expansion valve (item 3) which is basically a pinhole that causes the liquid to form a mist. A sudden pressure drop and material expansion when the liquid turns into a mist results in a rapid cooling of the fluid as it throws off heat energy. This cold mist travels through the evaporator coil (item 4) which is located directly in the air stream of a circulation fan which pulls air from within the building. The fan pushes the air across the cold coils, which pulls heat from the air, causing the air to cool. The transfer of heat to the refrigerant causes it to change back into a warm vapor and it enters the compressor to begin the cycle again.

Moisture Removal - Dehumidification

In addition to cooling internal spaces, air-conditioners also provide dehumidification. The original intent behind the invention of the air conditioner was to remove humidity from industrial spaces, with the cooling of the air considered a secondary effect. The removal of moisture during air-conditioning unit operation occurs when the relatively warm air of the building interior is pulled across the cold evaporator coils. Since physics dictates that warm air can hold more water than cool air, the cooling of the building air as it contacts the evaporator coils causes it to release moisture which forms as condensation on the coils. This condensation eventually drips off and is collected and drained off to the building exterior or to a sewer connection. A reduction in building humidity tends to improve the comfort level of the occupants by enhancing the effectiveness of the body’s natural cooling system. The combination of humidity removal and temperature decrease defines the “conditioning” of the air.

Refrigerants

Air-conditioning refrigerants typically consist of materials that are noncorrosive and have the ability to easily transition between gas and liquid phases at the operating temperatures of the air-conditioning system. Commonly used refrigerants are carbon dioxide, ammonia and chemicals called non-halogenated hydrocarbons, with the type of refrigerant selected based on the specific cooling application.

In the past, chlorofluorocarbons (CFC) and hydrochlorofluorocarbons (HCFC) were used, but CFCs were phased out of production in the 1990s and HCFCs will be phased out of production by 2030 because of their ozone depletion potential.