Architects must design high rise window washing systems carefully so that maintenance crews can safely access the facade to clean the windows. Many of the system manufacturers provide design assistance for a fee, but the design team should also review the system design with the cleaning vendor your client uses so that they can provide valuable input.

Local jurisdictions dictate the safety regulations surrounding window washing methods - always confirm the requirements of your local authorities. Generally, windows in buildings 3 stories tall or lower can be washed using ground-based lifts or telescoping window washing poles. However, for buildings over 3 stories in height, it might make more sense to wash the windows from a roof-based suspension system where the window washing crew is lowered from the roof. This article covers the basic suspension support systems for use with flat roofs; however, there are more complex systems based on these that can provide support from sloped roofs or other complex situations make the solutions below problematic. For these types of complex window washing problems, we suggest working directly with a window washing equipment manufacturer or consultant.

Window Washing Suspension Support

The first component of a high-rise window washing system is the suspension supports, which are located at the roof and carry the load of the work platform. These suspension components must be carefully designed in collaboration with the structural engineer since there are high moment forces applied to them.

Direct to Anchor Suspension System

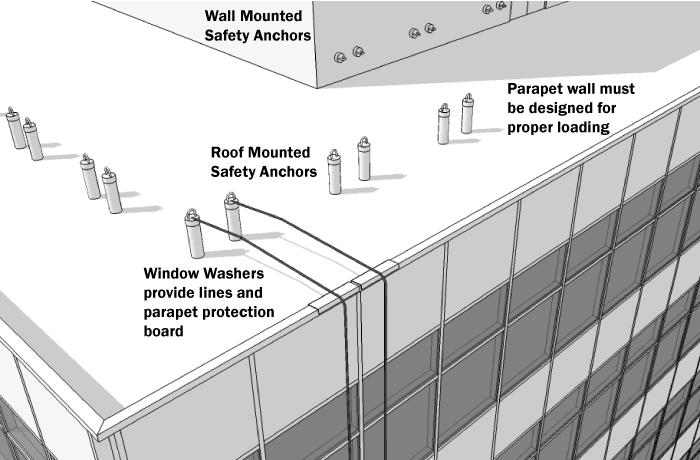

The most basic equipment for window washing and safety anchoring is the safety anchor or tieback. In this case, permanent anchors are secured to the building structure. The graphic below shows both roof mounted anchors and wall mounted anchors. The window washers then tie their safety lines to the permanent anchors and pass them over the parapet wall. A structural engineer must design the anchoring system and the parapet to carry the loads created by the lines and the window washer.

The following photo shows a series of safety anchors on the roof of a building. These anchors are bolted through the concrete slab, but they can also be welded to steel beams below the slab prior to the concrete being placed. In this photo, the roof insulation and roofing membrane have not been installed.

Portable Outrigger Suspension System

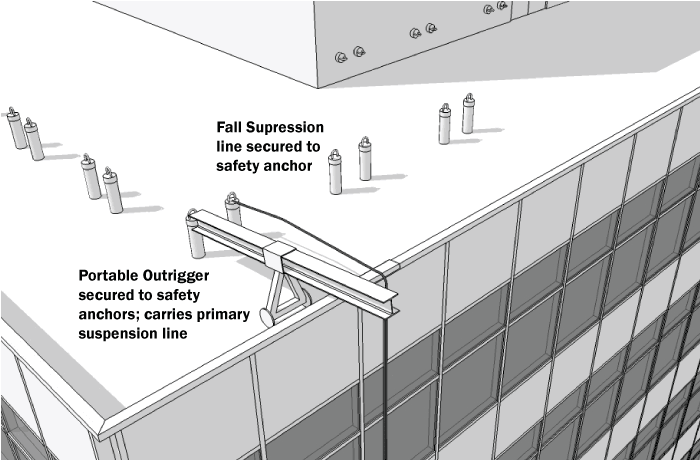

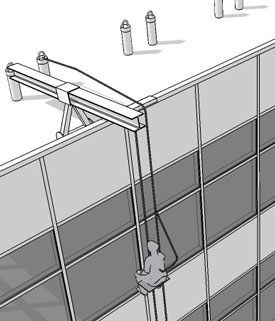

To remove the load from the parapet wall, a transportable outrigger is used. The transportable outrigger is a beam with wheels that secures to a safety anchor. The beam is adjustable and extends over the top of the parapet and the primary suspension line secures to the beam. In addition to securing the outrigger to the permanent safety anchors, metal plates are used to counterweight the outrigger. The image below shows the primary suspension line attached to the outrigger and the secondary fall arrest (emergency) line tied to a safety anchor. While this may be acceptable, using two outriggers is preferred to prevent any accidental load from damaging the parapet.

The photo below shows a portable outrigger system on the roof of a building during construction. In this image, the outrigger is secured with a series of metal plate counter-weights.

Davit Suspension System

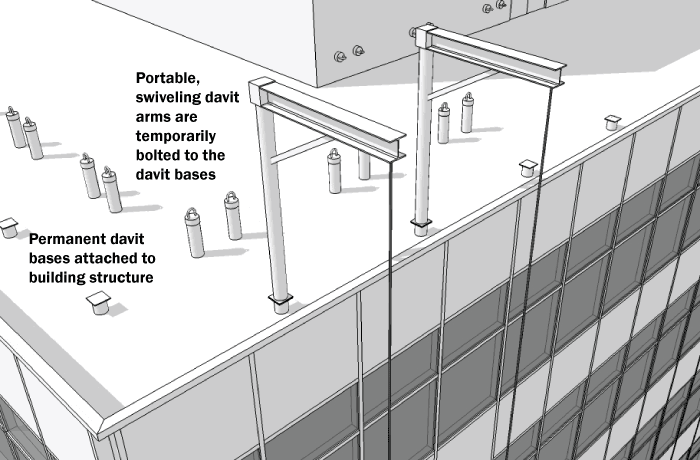

Another system for suspension of window washing equipment is the davit system. Davit bases are permanently attached to the building structure at a predetermined spacing. Davit arms customized for the building's specific conditions are secured to the davit base. Lines are suspended from the davit arm. The davit arms are generally swiveling, which allows washers to set up all equipment on the rooftop and then swing out over the parapet wall. Fall arrest lines are also used with this system, but have been removed from the graphic below for clarity.

Roofcar System

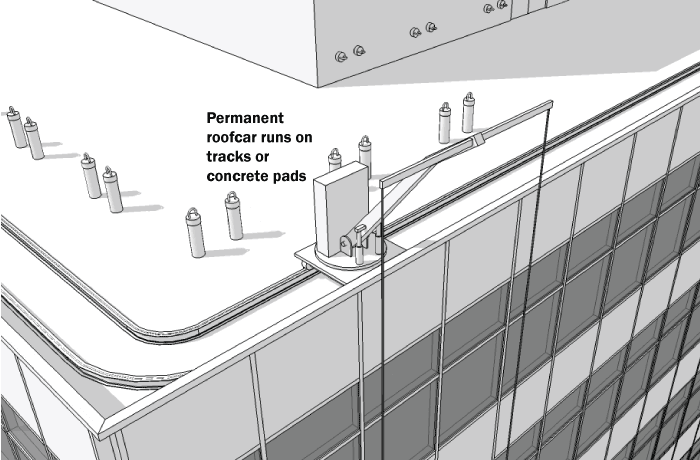

For buildings with high parapet walls, varying setbacks, or other complex forms, a roofcar system provides the greatest flexibility. The roofcar arm allows for a greater extension that other systems and can adjust without much setup time. The roofcar runs on rails or concrete pads and remains on the roof permanently. The single roofcar arm suspends both ends of the window washing staging.

Window Washing Work Platforms

Work platforms are hung from the support system and provide a working surface for the window washers.

Bosun's / Boatswain's Chair

Bosun's or Boatswain's Chair

Bosun's chairs are the most common form of platform used by window washers and facade maintenance crews. However, some companies and jurisdictions do not use them because of safety concerns.

The chairs carry a single person in the seated position. The diagram here shows the chair suspended from a portable outrigger system, but it can be used with any suspension system. There is always a secondary fall arrest line that is attached to the worker and tied to a different anchor than the platform. Bosun's chairs are descent controlled and cannot be used for ascending.

Cage Systems

Cage systems provide more flexibility than Bosun's chairs. Since the cages are powered by on-board motors, the cages can descend and ascend a building. In addition, cages come in various widths (generally up to 10 feet wide) allowing workers to access a wider area of the facade. The first diagram below shows a single-person cage suspended from a davit arm. The second diagram below shows a cage that is 10 feet wide, which can accommodate two workers, suspended by a roof car. There is always a fall-protection line provided for each worker and each of them must be tied to a different anchor.

Single Person Cage

Double Person Cage