Electrical conduit is a raceway or piping system that protects wires and cables from impact, moisture, and vapors. It is a path for either power or communication (low voltage) electrical wiring. It is usually tubular and made of metal (galvanized steel, stainless steel, aluminum) or non-metallic materials (plastics) and is either rigid or flexible. Special types of conduit are required for wet areas and hazardous areas. There are a number of different electrical conduit types, which we will discuss below.

In the United States, conduit installation falls under the tasks performed by licensed. NFPA 70, also known as the National Electric Code (NEC), provides information on the safe and proper way to install conduit and associated cabling.

The advantages of all types of conduit are that they:

- Protect electrical wires from damage due to abuse or accident

- Can allow for cables to be easily pulled to inaccessible areas in the future (i.e. inside finished walls)

- Allow wiring changes to be made simpler and safer

- Can be made waterproof or submersible

- Can be sealed to provide protection from fire and explosion hazards

The cost of conduit installation is higher than other wiring methods due to the cost of materials and labor. In residential, construction a high degree of physical damage protection may not be not required so the expense is not justified.

Two main categories of conduit body are considered here: metal conduits and non-metal conduit. Conduit systems can be differentiated by their wall thickness, mechanical stiffness, and tubing material. Conduit materials are often chosen for their mechanical protection, corrosion resistance, and the overall installation cost.

Types of Metal Conduit

Metal conduit comes in many forms and can be made from galvanized steel, stainless steel, or aluminum. Other types of metals are generally not used for conduit.

While metal conduit may sometimes be used as a grounding conductor, conduit circuit length is limited and it is safer to use cables that include a ground wire.

Rigid Metal Conduit (RMC)

RMC is a thick-walled, threaded tubing. It is generally made of coated steel, stainless steel, or aluminum. The conduit is connected together by screwing connectors to the main tubes. Rigid metal conduit provides significant protection from impacts and other damage. It can be used as a grounding conductor for short runs, but it is best practice to use wiring that has a grounding wire. The thicker walls of RMC protects the cables inside from electromagnetic interference (EMI), which can be harmful to sensitive equipment.

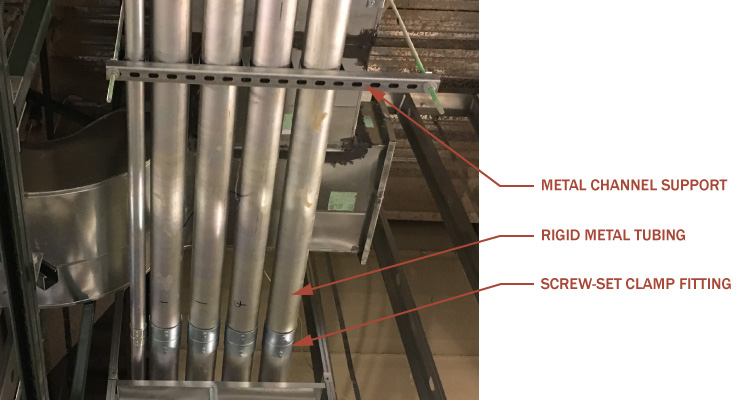

The following image shows rigid metal conduit with threaded screw fittings. The conduits are hung from metal channel framing.

RMC can be made corrosion-resistant by applying a coating such as PVC or by galvanizing the metal. The corrosion protection resists damage from water or other chemicals that can degrade metal. There are three common types of corrosion treatment:

- Galvanized Rigid Conduit (GRC), which is the most popular form of RMC, is used in commercial and industrial buildings.

- PVC-coated aluminum, which is suitable where chemical fumes that are corrosive to steel are present.

- Bronze alloy, which is suitable for coastal areas, chemical plants, oil refineries and underwater situations.

- PVC-coated rigid steel, which is resistant to oils, grease, acids, alkalis, and moisture and is flame-retardant.

When cut, the ends of rigid metal conduit should be reamed (remove burrs and rough edges) to protect the wire insulation from abrasion. In addition, any fittings should match the type of metal used for the conduit tubing to prevent problems from galvanic action.

There are two main disadvantages to using rigid metal conduit. First, since all connections are threaded, there is much more labor required when installing the system – this makes RMC much more expensive. Second, the thick walls of the tubing make the conduit much heavier, which also makes installation more labor intensive and expensive.

Electrical Metallic Tubing (EMT)

EMT is an unthreaded, thin-wall metal tubing generally made of coated steel, though it may be made of aluminum. It is a popular choice for electrical conduit in commercial buildings, but is generally not used in residential buildings. EMT is connected together using clamp-type fittings that slide onto the tubing and then are secured with a set-screw. Electrical Metal Tubing is less expensive and 40% lighter than GRC.

The following image shows electrical metal tubing with clamp fittings. The conduits are supported from metal channel framing.

While EMT provides a good amount of protection for the cables inside, it should not be used in hazardous areas where it is exposed to sever damage (like power plants or around vehicular traffic.) EMT is not suitable for wet areas or where corrosive fumes and vapors exist – special corrosive-resistant tubing and gasketed clamps are required in these areas.

Like RMC, the cut ends of the tubing must be reamed to remove all sharp edges.

Some electricians are skeptical of using EMT in critical areas because the set-screws in the clamps can loosen over time. In order to prevent this, a torque wrench or driver can be used to be sure the screws are set to the correct tension as required by the manufacturer.

Intermediate Metal Conduit (IMC)

As its name suggests, Intermediate Metal Conduit (IMC) has walls that are thinner than RMC, but thicker than EMT. Thus the weight of IMC also falls between RMC and EMT. Intermediate Metal Conduit is threadable, but it can also be un-threaded and used with clamp-type fittings. IMC is generally made from steel and can be coated.

Flexible Metal Conduit (FMC)

Flexible metal conduit (FMC) is typically available in diameters between 3/8" and 3", but larger sizes can sometimes be found. It is made by coiling self-interlocked aluminum or steel strips, which forms a hollow tube that wires can be pulled through. FMC comes in a standard wall (sometimes called full wall) thickness or a reduced wall thickness. Most manufacturers also produce an extra-flexible FMC for tighter bend radiuses, but this is generally not UL approved.

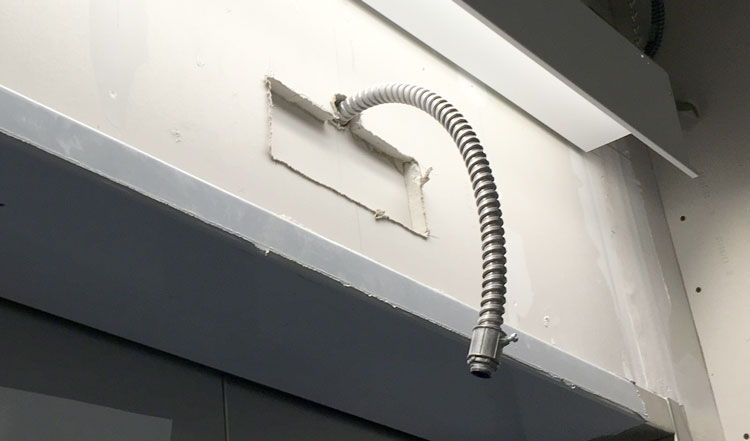

The following photo shows flexible metal conduit with a connector attached to the end:

Standard FMC is recommended in dry areas where it would be impractical to install EMT or other non-flexible conduit, yet where metallic strength to protect conductors is still required. Because of its flexibility, the FMC can help reduce vibrations from passing from motor to structure through the conduit.

Liquid-Tight Flexible Metal Conduit (LFMC) is FMC covered by a plastic waterproof coating. Its interior is similar to FMC, but it is suitable for wiring in wet or damp locations. It can also be buried in the ground or embedded in concrete. There are many types of LFMC on the market depending on the type of resistance needed, including extreme temperatures, oil resistant, anti-bacteria, flame resistant, and reinforced. It also comes in various jacket colors for easy identification. LFMC used for computer wires is usually blue.

It is important to note that Flexible Metal Conduit is NOT the same as metal clad (MC) cable or armored cable (AC). MC cable and armored cable include permanently integrated conductors in the flexible metal armor. However, flexible metal conduit is a raceway that the conductors are pulled through AFTER installation.

Types of Non-Metal Conduit

Non-metal conduit is made of plastic, also called PVC. It is used in areas where metals can cause problems. It is also used where it will be in contact with water, such as below ground or encased in concrete. PVC conduit will not rust or corrode when exposed to water. However, it is important to note that non-metallic conduit will not serve as a redundant ground conductor so you need to review local codes to ensure than non-metallic conduit is acceptable for your application.

Rigid Nonmetallic Conduit (RNC)

RNC is the lightest conduit available and is generally the least expensive. Fittings slipped onto the tubing and welded with a solvent, which is faster than the fittings used in metal conduits. In addition, the welded joints are water-tight. Plastic conduit can be heated with special tools so that it can be bent in the field, but there are also premanufactured sweeps or bends that are appropriate for plastic conduit.

RNC Pipe is most commonly available as schedule 40 or schedule 80 pipe, but can also be manufactured in other sizes and wall thicknesses. It is also available in extra-heavy wall thicknesses for areas where extra protection is needed; however, thicker walls make the conduit harder to bend.

The main disadvantages are that plastic conduit will not stand up to impacts as well as metal conduits. In addition, plastic conduits cannot be used for grounding, so a grounding conductor will need to be pulled along with the other conductors. Finally, plastic conduit expands and contracts more than metal conduit when exposed to heat, which needs to be taken into account when designing long runs.

Electrical Nonmetallic Tubing (ENT)

ENT is a thin-walled corrugated tubing that is flexible so it can be bent without special tools, however it will not permanently hold the bend. It is easier to install than RNC because it can be routed around obstructions without cutting and welding the pipe. Special ENT connectors are used – these are generally snap-in connections and are not watertight.

Liquid-Tight Flexible Nonmetallic Conduit (LFNC) is also available for use where the conduit will be subjected to moisture.