There are a number of different systems available for providing a fire rating while also maintaining light passage and a clear view. Fire rated rooms and stairwells do not necessarily need to be solid walled and dark – architects can specify glazing systems or glass opening protectives to keep a space filled with natural light.

It is important to note that the glazing systems and specialty glass products listed below are more expensive that standard safety glass types like laminated or tempered glass (we have another article that covers standard glass types). Architects must consider the cost of the material and their design goals before specifying vast areas of fire glass.

Fire-Protective vs. Fire-Resistive

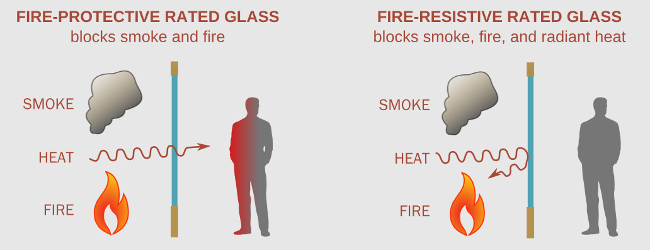

The first thing to consider when specifying rated glass is what you are trying to protect against. There is an important difference between fire-protective glass and fire-resistive glass and the building codes are very specific about where each are to be used. Architects should be sure they understand the difference and that they have clearly documented where they each type is required.

Fire-protective glass prevents the spread of fire and smoke. However, it will not prevent radiant heat transfer. That means that as the glass heats up from fire on one side, objects on the other side of the glass will feel the heat. Wired glass, specially tempered glass, and glass-ceramics are considered fire-protective glass and can generally be used where the building code calls for an opening protective.

Fire-resistive glass prevents the spread of fire and smoke; in addition it also stops radiant and conductive heat transfer so that objects on the protected side do not get hot enough to spontaneously combust. This is generally achieved by creating a laminated assembly that is composed of a number of layers of glass separated by heat resistant interlayers. Fire-resistive glass is used where the building code calls for a fire-resistive assembly, which also means that the temperature-rise on the protected side must be below a threshold (usually 250 degrees in rise beyond ambient).

Fire Rated Glazing Labels

The International Building Code requires that fire-protective and fire-resistive glazing assemblies have a permanent label that indicates what criteria the glass meet. In addition, the label identifies the amount of time, in minutes, of the rating. This is important because the building codes only allow certain types of glazing depending on the type of wall, the size of opening, and the type of opening. The label should never be removed or concealed.

International Building Code table 716.3 provides information on the markings used on fire-rated glazing – we are providing that information below:

| MARK | DEFINITION | TEST STANDARD |

|---|---|---|

| W | Meets wall assembly criteria | ASTM E 119 or UL 263 |

| OH | Meets fire window criteria including hose stream test | NFPA 257 or UL 9 |

| D | Meets fire door assembly criteria | NFPA 252 or UL 10B or UL 10C |

| H | Meets fire door assembly hose stream test | NFPA 252 or UL 10B or UL 10C |

| T | Meets 450-degree-F temperature rise criteria for 30 minutes | NFPA 252 or UL 10B or UL 10C |

| XXX | Time, in minutes, of the fire-resistance or fire-protection rating of the assembly | N/A |

Be sure to check codes for the local jurisdiction before selecting the type of glass used in a rated wall. Information on fire rated glazing can be found in the Opening Protectives portion of the code.

Wire Glass

Wire mesh glass was, for a long time, the only type of rated glazing available. It is made from a sheet of glass that has a wire grid mesh incorporated into it. The wire holds the glass in place when it is exposed to the high heat of a fire. However, the wire makes the glass less durable so it is more prone to breakage due to impact. In addition, the wire creates a more jagged breakage pattern, which is very dangerous. Due to the safety concerns, many building codes no longer allow wired glass in doors or sidelights, especially in schools and gymnasiums.

Safety wired glass has the same fire-resistant properties of normal wire glass, but it also has film that allows it to meet safety requirements so it can be used in doors and sidelights. The film holds the glass in place if it were to break so that broken pieces will not cause injury.

The biggest benefit of wire glass is the low cost compared to other types of fire glass. However, other options are starting to become more competitive.

Specially Tempered Fire Rated Glass

A cost effective alternative to wired glass is tempered glass that has been tested and has a fire-rated label. However, there are two main drawbacks. First, it will usually not be able to survive the hose stream test. Second, since it can’t pass the hose test, tempered fire glass carries a maximum rating of 20-minutes so it has limited use.

Ceramic Glass (Glass-Ceramics)

Ceramic glass, usually referred to as glass-ceramic, is a glass product that resists high heat levels. Because it can handle 800-degree-F changes in temperature, glass-ceramic is used for glass cooktops and fireplace doors, but it is also suitable for fire rated glazing with a rating up to 3 hours.

Glass-ceramic is made from a normal sheet of glass. The pane gets a heat treatment that causes a crystallization process, which must be carefully controlled. The crystallization creates a stronger piece of glass that has high thermal stability.

Ceramic glass is a versatile product. It can be tinted, clear, or mirrored. It can also be included in insulated glass units (IGUs), which can contribute to energy efficiency. Due to its range of aesthetic offerings, glass-ceramic is quickly becoming a popular choice for fire rated glazing.

Intumescent Glass

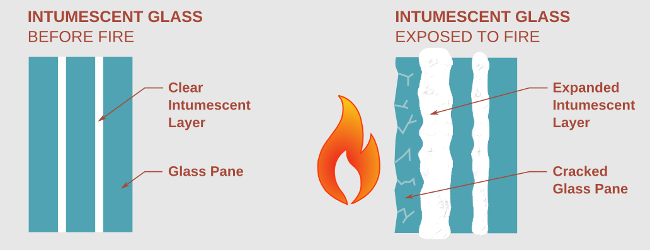

Intumescent fire rated glazing is a laminated product made up of alternating layers of glass and clear intumescent inner layers. The fire rating can be up to 3 hours depending on the number of inner layers used.

When exposed to a fire, the outer layer of glass shatters. The intumescent inner layer holds the broken glass in place, but it also rapidly expands to provide an insulated layer of protection that prevents the spread of fire and smoke as well as preventing thermal heat radiation.

The main benefit of intumescent glass is that it prevent thermal heat radiation so it can be used in a fire-resistive assembly as long as it has been tested and is labeled for that use.

Fire Rated Framing Systems

It is important to note that both the glass and the framing system work together to provide a fire rating, which is why we use the word “assembly” regularly in this article. Both the frame and the glass should have the same rating; although, the building codes do provide exceptions where a higher rating than required is allowed (always refer to local codes when designing a system).

Where a system of different components is used, all components should be properly labeled so that the ratings are clear and can be checked in the field. Fire rated systems are critical life safety components and need to be thoroughly reviewed in both the design and construction phases to ensure they meet code requirements.

Fire Rated Glass Testing

Fire rated glass is tested the same way that other fire rated materials are tested. A wall is built in the side of a furnace. The glass systems are installed into the wall just like they would be installed in the field. Then a fire is created in the furnace at the prescribed temperature and left to burn for the amount of time required for the test. The glazed assembly must remain intact as specified in the testing criteria.

In the United States, a second test is performed where a stream of water is applied to the hot glass to test impact resistance. For more information on this test, refer to the Hose Stream Test, below. Other countries use a weight dropped on the glass to test the impact resistance.

For more specific information on the testing procedures, we suggest that you review ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials, NFPA 252: Standard Methods of Fire Tests of Door Assemblies, and NFPA 257: Standard on Fire Test for Window and Glass Block Assemblies.

The Hose Stream Test

Rated assemblies must remain intact to provide protection. The hose stream test, which is mainly used in the United States, tests the structural integrity of a glazed assembly after it has been subjected to fire conditions. Originally, the test was used for all types of assemblies, not just glass. In addition, a weight was originally used for the impact, but that was since changed since a hose provides a more even and constant impact.

The procedure is fairly simple – an assembly is placed in a furnace for a period of time after which a 2 ½” hose directs a stream of water at the assembly. The cool water hitting the hot glass creates significant thermal shock stresses in the glass, which could cause it to shatter. In addition, the hose stream itself creates a lateral impact force on the glass. Both forces need to be resisted in order for the assembly to pass the test.

This video by Technical Glass Products shows an example of the fire hose stream test and also demonstrates the idea of thermal shock.

NFPA 257 provides the testing requirements and performance criteria. The criteria varies based on the type of assembly, but essentially the unit must remain in place and openings due to breakage must not exceed a certain size.

There is great debate around whether the hose stream test should continue to be used to evaluate fire rated glazed assemblies. Those in favor of the test argue that it provides good information about how a glazed assembly will react under thermal shock stresses. Critics claim that the thermal shock stresses don’t apply since modern sprinklers are activated well before the glass gets hot enough to be affected by water spray. The debate will continue, but for now, the hose stream test still applies in the United States.